| ITEM | SPECS |

| Width | 1000 (mm) |

| Maximum Length | 27 (m) |

| Minimum Length | 2 (m) |

| Panel Thickness | 40, 50, 60, 80 (mm) |

| Core Thickness | 50 (mm) |

| Zinc Coating | G 180-60 gm/m² |

| Washington Thermal Resistance | 2.48 m² K/W |

| Internal Facing Steel Thickness (mm) | Micro-ridged lightly profiled metal sheet |

| External Facing Steel Thickness (mm) | ?? |

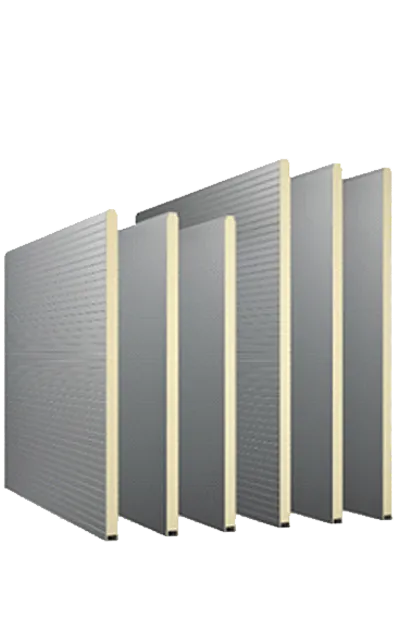

Wall Panels

Products

Wall Panels

Wall panel sandwich manufactured under ICPS brand contains double tongue and groove joints to facilitate assembly and provide the best thermal insulation and joint tightness. They are supported by continuous foamed sealing tape to prevent dust penetration and (1-3 mm) gap to prevent thermal expansion effects. The external and internal steel of the wall panels is covered with polyethylene film to keep from scratches during transportation and installation.

Panel Application

Wall sandwich panels find diverse applications across various industries and building types. These applications include commercial structures, industrial complexes, residential dwellings, military installations, healthcare facilities, educational campuses, agricultural buildings, sports venues, oil fields, and power generation plants.

Technical Information

Download Brochure

| Panel Thickness (mm) | 40 | 50 | 60 | 80 | 100 | 120 |

|---|---|---|---|---|---|---|

| W/M²K | 0.62 | 0.44 | 0.37 | 0.28 | 0.22 | 0.19 |

| Kcal/m²h˚C | 0.47 | 0.38 | 0.32 | 0.24 | 0.19 | 0.16 |

| Sheet Thickness (mm) | Nominal Panel Thickness (mm) | ||||||

|---|---|---|---|---|---|---|---|

| 40 | 50 | 60 | 80 | 100 | 120 | ||

| 0.4/0.4 | kg/m² | 7.9 | 8.3 | 8.7 | 9.5 | 10.3 | 11.2 |

| 0.5/0.4 | kg/m² | 8.6 | 8.0 | 8.4 | 10.2 | 11.0 | 11.8 |

| 0.5/0.5 | kg/m² | 8.2 | 8.6 | 10.0 | 10.8 | 11.6 | 12.5 |

DiscoverMore